12 month manufacturer warranty on all accessories.

Why Use a Pressure Differential Gauge

When screw anchoring a torque reading is required to ensure the pile/pier has been screwed in to the

correct specification. Project engineers will generallly demand that a specific torque amount is reached

depending on what the piles or piers are being used for.

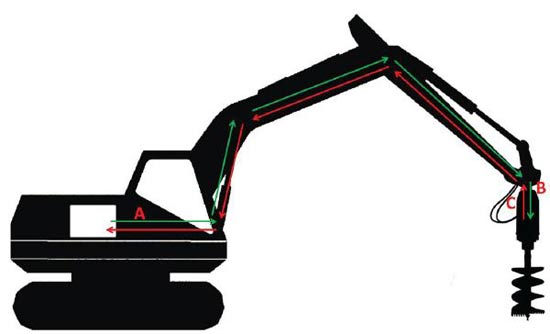

Traditionally, torque is calculated by a single sensor located at the hydraulic pump (A) in the excavator.

Unfortunately this is not accurate as pressure is lost as oil travels up the boom through the drive unit

and back again long the boom to the excavator. Pressure readings can be out by as much as 15-20%

compared to actual working pressure.

Digga’s Pressure Differential Gauge comprises of two sensors - The first sensor located on the supply

line at the entry to the drive unit (B). The second sensor is located on the return line where oil leaves the

drive unit (C).

A micro processor calculates the ´actual usable´ pressure using the two sensors, giving a reading

which is up to 12-15% more accurate than the traditional method.

The reading is displayed in BAR or PSI (depending on the option chosen at the time of purchase). This

figure is compared to a supplied torque chart to obtain the pressure reading in ft-lbs or Nm.